What is Preventive Maintenance?

As the old saying goes, an ounce of prevention is worth a pound of cure. That could be described as the mantra of preventive maintenance (PM), a maintenance method involving regularly scheduled maintenance of machinery and other assets in order to keep them running smoothly. If the day-to-day operations of your small business are reliant on machinery, you know how disruptive it can be when a piece of equipment breaks down or doesn’t perform as it should.

This guide will walk you through basic questions about preventive maintenance as well as what’s typically involved in the creation of a preventive maintenance program. We’ll also discuss the types of businesses that would benefit most from this maintenance method, as well as some challenges you should keep in mind.

What is preventive maintenance?

Preventive maintenance is the set of practices businesses follow to keep equipment in working order. It can also be referred to as preventative maintenance or proactive maintenance. The term also describes an application of computerized maintenance management software (CMMS) systems, as discussed in the video below.

Preventive maintenance programs help businesses manage preventive care of their assets, as opposed to corrective maintenance or reactive maintenance, where tasks are performed only when needed or when equipment has already broken down.

According to Gartner, preventive maintenance can be time-based, in which recurring maintenance jobs are scheduled based on the time of their last occurrence, or usage-based, in which jobs are scheduled based on usage data from equipment such as hours, kilometers, or flow (full content available to Gartner clients). Usage-based preventive maintenance can also be described as predictive maintenance, which relies on the use of condition-monitoring sensors to anticipate and prevent equipment failure.

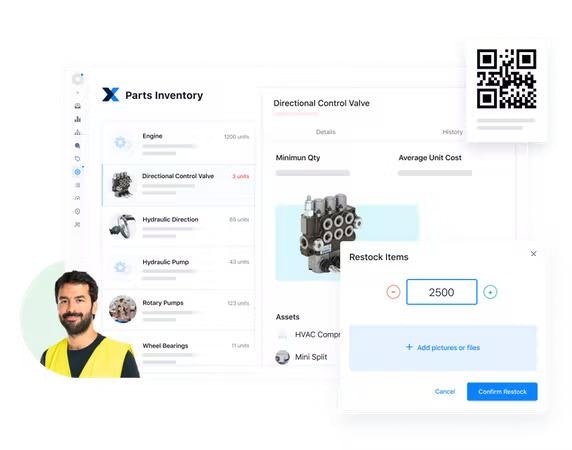

As its name suggests, preventive maintenance depends on the planning and scheduling of maintenance before something goes wrong. It requires meticulous record keeping of previous maintenance and inspections as well as in-depth knowledge of each part of your machinery, when it was installed, and what the expected lifespan is of each part so that you know when to replace it. Preventive maintenance software, such as the example shown below, can track all of this information to make these processes easier.

Inventory management feature from MaintainX, a web-based CMMS tool (Source)

What makes preventive maintenance so important?

Preventive maintenance is important because it allows for more efficient facility management. It is widely considered to be preferable to and more cost-effective than corrective or reactive maintenance. When you forgo routine maintenance in favor of maintaining equipment as needed, there are more variables that are beyond your control, such as the cost of repairs and duration of downtime.

Other benefits of preventive maintenance include:

A safer working environment for your employees

Increased productivity

More reliable equipment

Fewer interruptions to day-to-day operations

What does it take to set up a preventive maintenance program?

In addition to meticulous record keeping, preventive maintenance also requires very careful planning. The following tips will help prepare your business for a preventive maintenance program that fits your needs:

Gather and record information on your assets. Original equipment manufacturer (OEM) manuals are a good place to start. There you can find detailed information about different equipment parts, serial numbers, and inspection frequencies.

Take inventory of your equipment. A critical step in risk-based preventive maintenance, taking inventory of your equipment requires that you pay special attention to which assets are most important to your day-to-day operations. A critical asset is one that would be the most disruptive if it were to break down, and should be prioritized as you come up with a preventive maintenance strategy.

Establish resources for each preventive maintenance task. These resources can include:

Spare parts and manufacturer information so that they can be reordered when needed.

Photos, diagrams, or other documents associated with each asset.

Instructions for inspection of each asset.

A maintenance log so you can keep track of each asset’s repair history.

Safety information.

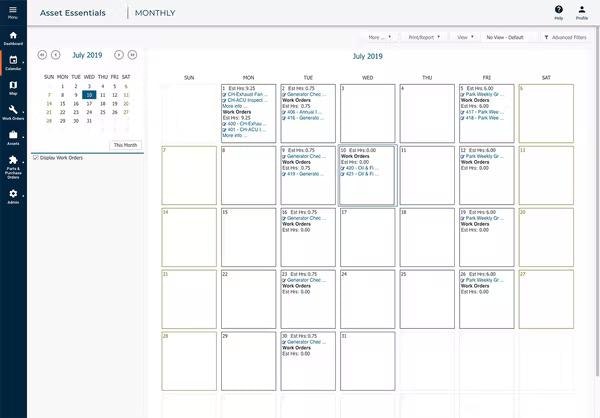

Create long- and short-term schedules for each asset. First, create a long-term schedule for each critical asset, and set up either time- or usage-based recurring maintenance plans (manufacturer recommendations will tell you which).

Example of a preventive maintenance schedule from Brightly Asset Essentials (Source)

Then, you can focus on short-term schedules, which is what your week-to-week preventive maintenance tasks will look like. A project management (PM) task can include cleaning, ventilation, lubrication, chain or belt adjustments, oil changes, or the inspection, repairing, or replacement of various parts.

Train your employees on all of the preventive maintenance tasks you have planned, their schedules, and the resources available to assist with these processes.

Again, preventive maintenance software makes it easy to keep track of all of this information, and can also house OEM manuals so that you can easily access instructions and other documents as needed.

Who should use preventive maintenance?

Any business that relies on equipment for its day-to-day operations would benefit from preventive maintenance. Here are a few specific examples:

Manufacturing

Any business that manufactures products using machinery is a great candidate for preventive maintenance, whether it’s producing furniture, cars, shoes, or potato chips.

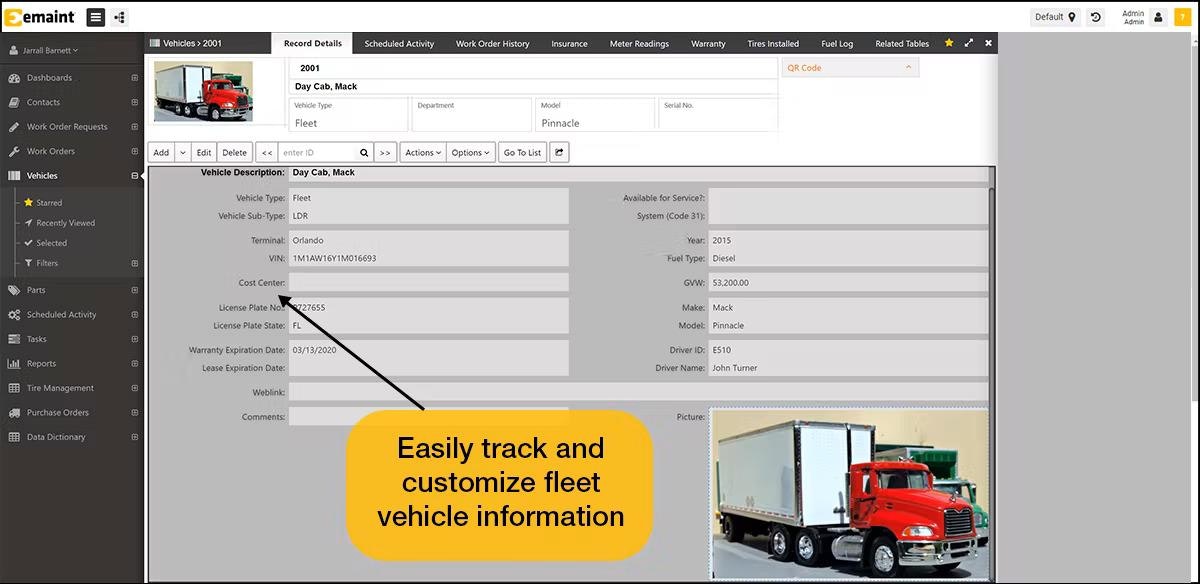

Fleet management

Moving, shipping, and construction companies all rely on vehicles. Preventive maintenance ensures that company vehicles are in good shape to carry out daily operations and transport drivers safely. See the image below for an example of preventive maintenance software used for fleet maintenance management.

Fleet management function in eMaint CMMS, a cloud-based CMMS tool (Source)

Commercial real estate

Whether you’re renting out apartments or brick-and-mortar storefronts, preventive maintenance ensures that appliances and HVAC systems are in working order.

Medical

Preventive maintenance is especially important for hospitals and medical practices, where the ability of equipment to function properly can have serious consequences.

If your business has a lot of equipment, such as the examples listed above, preventive maintenance software is a must-have. The primary objective of preventive maintenance software is to prolong the life of an asset with a preventative upkeep schedule, which maximizes asset value and limits unnecessary replacement costs. It achieves this by scheduling regular equipment upkeep, reducing downtime by combining routine tasks when possible, and subsequently reducing repair-based expenses and losses resulting from delayed or halted production. It also allows your maintenance team to keep track of work order data so that unplanned maintenance work can be accommodated in addition to regular maintenance.

Preventive maintenance is worth the effort

While the benefits of preventive maintenance are numerous, a preventive maintenance program can present challenges:

Upfront costs can be substantial. You might need to hire more staff or purchase additional equipment to ensure that your existing assets can perform optimally. Preventive maintenance software can also be expensive. If you’re operating on a limited budget, you might be persuaded to keep track of equipment maintenance manually, which leads us to our next point.

It can be tedious. Preventive maintenance can be time-consuming and labor intensive. Inspecting and taking inventory of equipment requires a commitment of time as well as attention to detail.

It can be overwhelming. If you have hundreds or even thousands of assets to maintain, organizing and implementing any sort of preventive maintenance strategy can be daunting.

Still, preventive maintenance is the method of choice for businesses relying on machinery for the reasons we covered earlier: It’s more cost-effective in that it offers a high return on investment, and it allows for more efficient facility management. And if it’s within your budget, preventive maintenance software will mitigate the challenges listed above by automating processes and keeping records for you.

To get started on your own preventive maintenance plan, browse our list of preventive maintenance software.

Note: The applications mentioned in this article are examples and are not intended as endorsements or recommendations.